Premium Engineering Services

Comprehensive CNC machining solutions backed by cutting-edge technology and decades of expertise

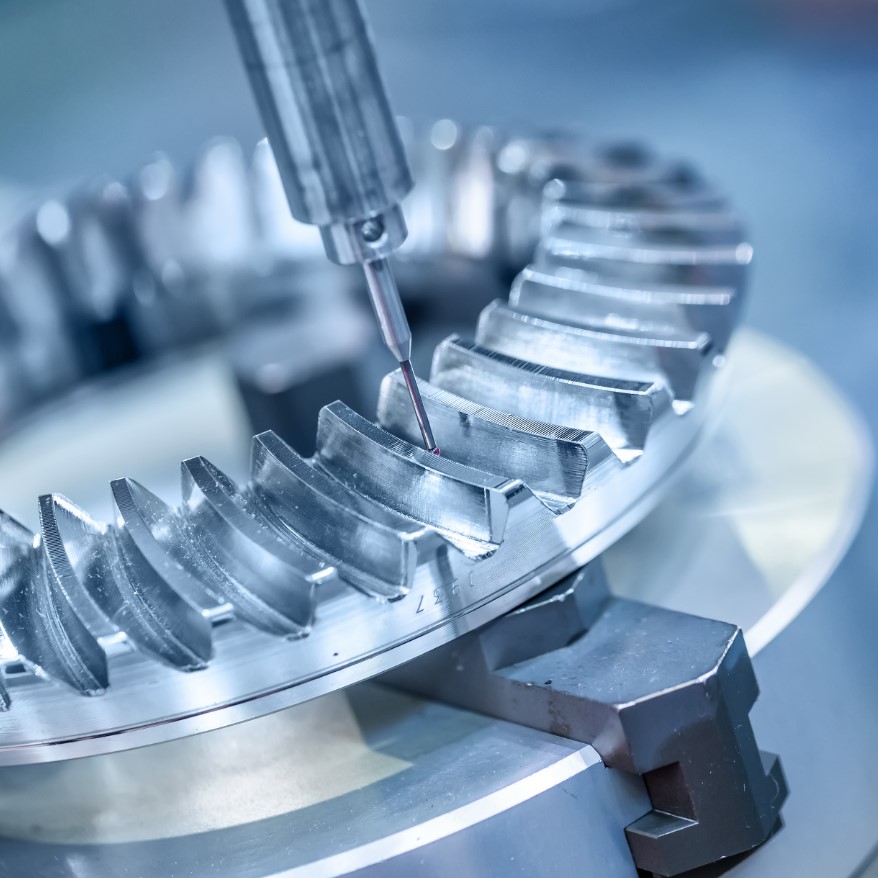

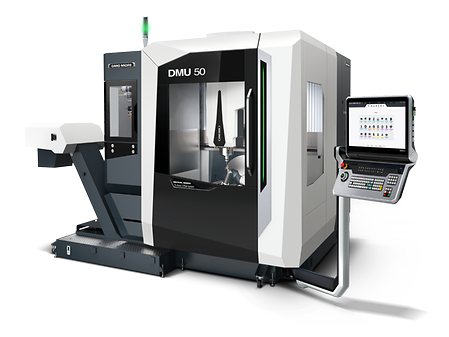

5-Axis CNC Milling

Advanced multi-axis machining for complex geometries and tight tolerances

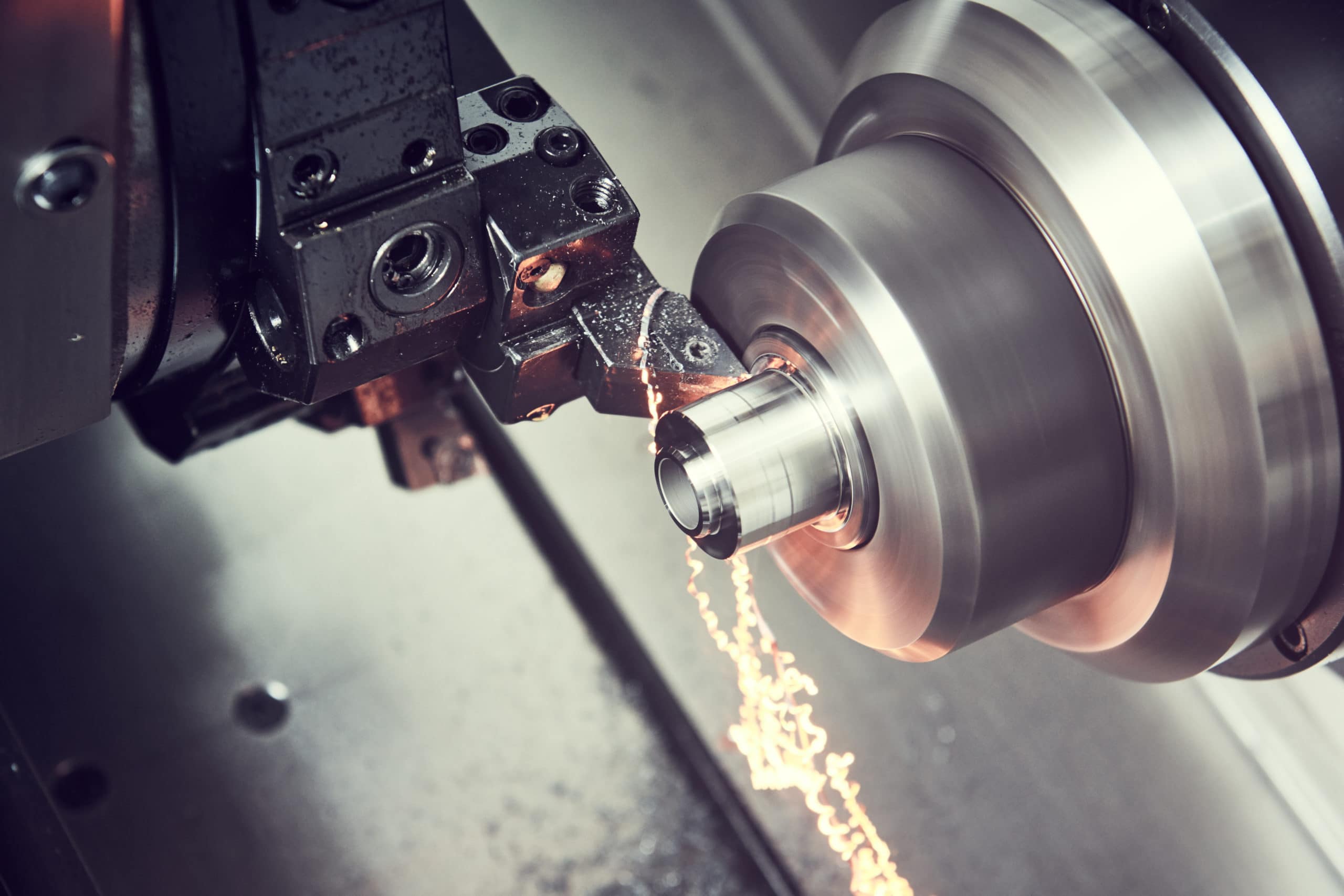

Learn morePrecision CNC Turning

High-precision turning services for cylindrical components and complex profiles

Learn moreRapid Prototyping

Fast turnaround prototype manufacturing to accelerate your product development

Learn moreReverse Engineering

Advanced 3D scanning and modeling for accurate replication and improvement

Learn moreDesign Consulting

Expert guidance for optimizing designs for manufacturing and performance

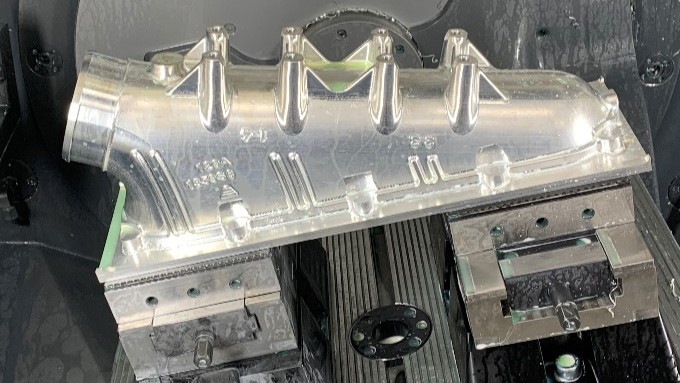

Learn moreOur Products

Precision engineered components and custom solutions for various industries

Learn more